No Product in the Oven. WINCON is attempting to establish a communications link with the furnace shown in flashing black text and yellow background. The board will operate with only a 15 volt DC power supply. All the possible options are: There is Lithium battery pack on every FCU board to maintain data time and configurations for a ten year period.

| Uploader: | Tukinos |

| Date Added: | 17 August 2009 |

| File Size: | 40.26 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 91765 |

| Price: | Free* [*Free Regsitration Required] |

The board will operate with 24 volt DC power supply.

softare Run the Shutoff Recipe. With the internal function of RCS defined, the Product Tracking interlock will function along with software timer values used in the Rail Configuration?

Tying an additional output to the to the Auxiliary equipment named Heat can still be done if desired for certain applications. Turn on the Furnace and PC 8.

Waiting the Wincon linking. These conditions are checked all the time the Oiler is On in the Recipe, and if at any time any one of these conditions are not met the Oiler output will be Unasserted. No other external connections and apparatus are need for it to operate.

This allows the FCU board to maintain information on how long it has been on or off and all calibration values. Unplug the RS ports 8.

Waiting going to Ready. Optionally an output bti be assigned along with the internal function Heat, and it will behave the same as the Heater Power Output with the exception that a duty cycle and time period can be assigned to this output whereas none can be applied to the Heater Power Output Additional internal function Heat controls: Turn on the Furnace and PC 9.

Under normal operating conditions, exposure should not occur. Proximity Switch Sensing Range: Conveyor is maintained running. Turn off the Furnace for 10 seconds 7. Run Defrag twice, if it needs it or not 5.

Tying an additional output to the to the Auxiliary equipment named Conveyor can still be done if desired for certain applications. Lockable Power Disconnect Switch 5. Optionally an output can be assigned along with the internal function Conveyor, and the output will turn on and off based on the assertion level when the conveyor is turned on and off in the Recipe. The Oiler status information is displayed in the Setup Status dialog.

The analog outputs can also used independent of inputs. All the possible options are: IDLE After changing the recipe, the furnace stays in the SETUP state until the temperature reaches the alert band and remains within this band during the preready dwell time with no alarms.

Shorted within the Zone 3.

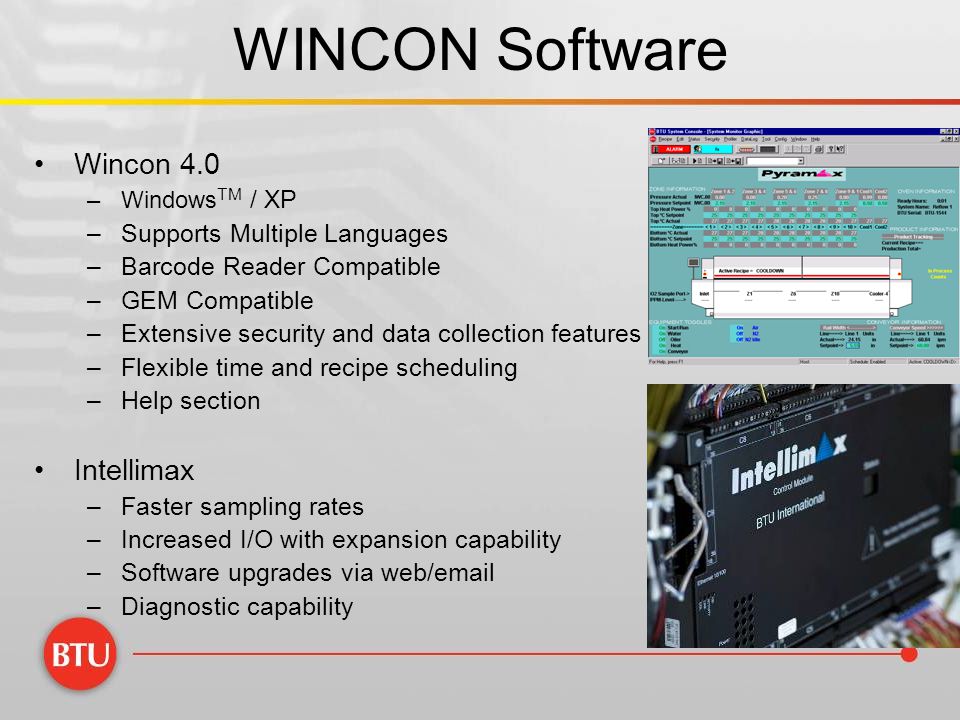

BTU training document

Turn on the facilities power switch. Pushing the Master Start Buttom. The top right drawing section has a reference pointer coming in from the top, this indicates an input and shows where the input is coming softare. There is Lithium battery pack on every FCU board to maintain data time and configurations for a ten year period.

These ports are used to control heated zones, static pressure in a close loop configurations. The initialization process may take several seconds.

BTU training document |

Black text, yellow background. Anti-Virus, Profiler software, etc. Over Temperature Protection 3. You must correct the problem to clear the alarm. Additional contacts may be added.

Комментариев нет:

Отправить комментарий